|

Two-loop windmill for stable energy supply Project substantiation p. 4 |

|

Solar batteries also are not widely applied in addition with windmills, as they cost much and are not reliable as a doubling source. One of such circuit designs is shown in Fig. 13 [2].

|

|

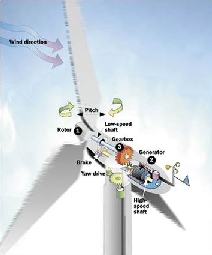

Fig. 13

|

|

Besides, there exists a project how to combine a windmill and a power station working on the sea-wave energy. ōGenerally, there has been patented multitude of power plants working on the sea-wave energy (tidal and others)ģ inexhaustible, environmentally clean energy source. However, the authors tried æto saddleÆ only some definite kind of wave energy, and such devices yet did not found their serious application. Shpakov endeavoured making his creation multipurpose and able carrying out different and even unexpected functions. His plant is a disk-shaped buoyant platform 1 (such kind of buoyant soup-plate) 8-10 meters in diameter and 250 tons in displacementö [16], see Fig. 14.

|

|

Fig. 14

|

|

With all originality of this construction, it has same demerits as all windmills ¢ inconstant energy source and energy space-dissipation. And this principle considerably limits the power of mills by the optimal size of plates (connected with the wave period), as well as by the problem of overgrowing seaweed and corrosion of hinge joining the disk 1 with the counterweight 2. Thus, the efficiency of doubling wave source for the 70-200 kW windmills is doubtful. So inertial unit with the platform, generator and all ancillary equipment, with the wave energy 1-2 will not provide the declared power. And on the sea the calm wind coincides with the calm sea-waves, so the pauses of windmill will coincide with those of wavemill. Noting all these difficulties, most of designers prefer diesel-generators as an additional power source for medium- and high-power windmills. In particular, ōin the VDK, windmills serve as the main energy source, diesel-generators are auxiliary. It supplies energy to powerful consumers remote from centralised mainsö [5]. ōAt present, windmills are most convenient and affordable for private consumer alternative energy source. They give the following advantages: - independence of outside sources (like mains), no necessity to provide a wire to the remote places; - possibility to use them in combination with the mains and other sources (diesel-generators, solar batteries), considerably saving expenses and stabilising the power supplyö [17]. Thus, windmills are used either as an additional source or in combination with the diesel-generators. The exception is solar battery which, as we saw, do not provide complete independence and also need additional storage batteries. One of typical versions of such combination is shown in Fig. 15.

|

|

Fig. 15

|

|

Manufacturers see the following merits of such combination: ō- high quality at low price; - high degree of wind energy use; - possibility to use standard diesel generators; - kinetic energy of rotor rotation is used to lessen the number of starts of diesel generator; - possibility to work without storage batteryö [18]. Although such combination can provide an independent supply, it has demerits. The main of them are, first, the necessity in hydrocarbon fuel, and second, the necessity to use the diesel-generators of the same power as the nominal power of windmills, as they take the whole load when calm. And as we could see from the above computation, under the full load of windmill, the working time of diesel-generators can achieve about a half and more of the full working time of amount of devices. Actually, as the experts of WindPark company have computed, ōin the places with good wind resource it saves up to 80 % of fuel and moreö [5]. For the medium windmills such expenses for the energy produced by costly diesel-generators are not dramatic, but for those more powerful than 1 MW such power of diesel and consumption of hydrocarbon fuel cancels all other advantages except only full autonomy necessary for special aims. Furthermore, we see in the diagram that to provide independence and uninterrupted supply, we have to include into the circuit a controlling panel for each windmill and each diesel-generator to provide the matched work of each unit, as well as the central panel and the controlling panel of the whole amount of units. This is the next difficulty of wind power engineering. As we could see from the versatile types of above windmills, they all are based on the straight utilization of energy produced in interaction of windmill rotor with the air flow. With it, one more problem of wind power engineering is scattered wind flow. There exists the dependence between the calculated power of windmill, rotor diameter and flowed-about area. For example, for the mill VEU-30 the developed power at the speed of wind 10,5 m/s was 30 kW with the wheel diameter 12 m (the flowed-about area about 96 m2) [4]. For the powerful mill NEG Micon [6] having the rotor diameter 92 m (the flowed-about area is 5027 m2), the nominal power was 2750 kW. Thus, with this approach, the growing power inevitably leads us to the growing rotor diameter and hence ¢ to the growing height of windmill. In its turn it causes the growing problems of constructional instability and growing mass of rotating parts of mill. Possibly, the level of 5 MW approaches the limit for consol-construction windmills, as all large producers adhere not to the trend to augment the power of units but to create complexes like General Electric, WindPark or NEG Micon (see Fig. 3) supply. See also Fig. 16 for the chain of windmills mounted by the company Knight & Carver [19].

|

|

Fig. 16

|

|

The large number of units in one system makes a new difficulty. To match the produced energy in phase and amplitude, in inhomogeneous wind flow we have to line up with the weakest wind flows, lessening the efficiency of the system as a whole. In this order, and to stabilise the amplitude and frequency of voltage, powerful windmills have a complicated system offering to regulate the angle of attack of blades which is up to 13░ [14]. In fig. 17 we show two ways to control blades used in the windmills produced by Lianozovsky electromechanical plant (a) [4] and windmills Knight & Carver (b) [19].

|

a |

b |

Fig. 17

|

|

Additionally, as we could see in the Table 1, when achieving the nominal power, this regulation does not use the excessive wind flow whose lack will take place when calm and which will be substituted by hydrocarbon fuel burning, by connection to the mains or by discharge of storage batteries. In direct interaction of windmills with the wind flow and direct feeding of consumer, such problems basically cannot be solved, though most of these difficulties can be overcome through redistribution of the received energy in time with respect to the consumed energy. One more demerit is the high cost of windmills. According to the Table 3 [20], even the windmills that were in use before mounting cost much, which depends on, how long were they in use before.

|

|

Table 3

|

In the last column the Table 3 gives the payback time disregarding the exploitation expenses, if the cost of energy is $0,04 per kilowatt and if the windmill works a half of days yearly [13]. This table evidences that different producers give different payback time, for some types of windmills it is nearly equal to the total working time, and with growing power the payback time grows. This corroborates the above conclusion that constructional complexity of contemporary windmills grows with the power not in proportion. Hence, their efficiency can reveal itself only in the long-term future and individual consumer cannot achieve it, so it is thought prospective if the energy is produced by specialised companies having their own personnel for service and the main, able coordinating the flows of produced and consumed energy, which makes it cheaper. While for individual users large investments for long term become inefficient: with full load the total working time is about 15-20 years and payback time is at least 4 years. And today constructions do not fully provide the autonomous energy supply, which makes additional trouble to the individual consumer to combine the energy sources. With such many separate windmills, at some stage we encounter the problem o free place. Thinking of alternative production of hydrogen as the car fuel for England, experts have calculated that ōto provide with hydrogen all British cars, we would have to cram with windmills the whole Kingdom beach 10 km wide. Such a trifle as 100 000 turbines and itÆs æin the bagÆ, as the authors of this research have calculatedö [22]. Thus, we see that attempts to combine windmills with other energy sources like storage or solar batteries, diesel-generators do not fully solve the problem of stable energy supply, as they considerably raise the cost of produced energy. And we have to mark especially that with all today demerits, wind energy engineering is a highly profitable branch. Thus, in case of rotor windmill Aerolla, experts have evaluated that if the windmill works only 3300 hours yearly and 1 kW*hour of energy costs $0,04, ōThe yearly productivity of the mill is 330 000 kW*hour; The cost of yearly produced energy is 330 000 * $0.04/ kW*hour = $13200 The yearly fuel economy is 330 000 kW*hour * 0.3 kg/ kW*hour = 99 tons of conventional fuelö [13]. Noting that the cost of one ton of anthracite (whose calorific value is similar to the conventional fuel) on the world market is now about $60, the fuel economy from one windmill is about $5940, i.e. a half of cost of the energy produced by one windmill during a year, and lessening of hydrocarbon deposits speaks of further growth of wind energy efficiency. This means, we have to develop wind energy engineering, only seeking for more effective use of wind able providing stability and quality of produced energy with the least impact on the environment. |

--------------------------------------

Journal of laboratory Business-plan Substantiation of project